A general A-site alloying strategy for the preparation of noble metal-occupied MAX phases has been proposed by researchers from the Zhejiang Institute of Tianjin University, Linköping University, Sweden, and the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences, under the direction of Professor Qing Huang.

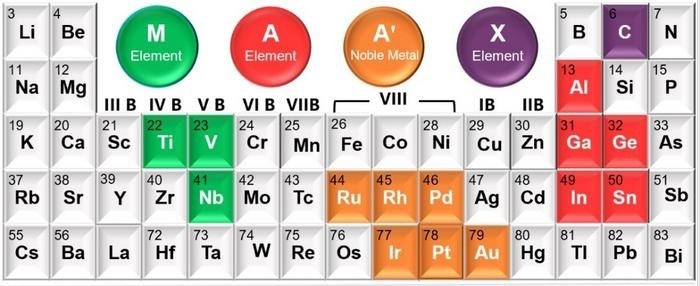

The periodic table with all elements incorporated in noble metal-occupied max phases that are produced via the general a-site alloying strategy. Image Credit: Ningbo Institute of Materials Technology and Engineering (NIMTE)

The periodic table with all elements incorporated in noble metal-occupied max phases that are produced via the general a-site alloying strategy. Image Credit: Ningbo Institute of Materials Technology and Engineering (NIMTE)

This work was published in the journal Matter. A family of ternary layered transition metal carbides known as MAX phases has garnered significant interest as a potential source of high-temperature structural materials.

Researchers have progressively broadened the conventional main group elements atom types in A-sites to encompass subgroup elements having an outer layer three-dimensional (3D) electronic structure. There has not been much study done on MAX phases with A-site elements that have 4d/5d orbital electronic structures, though.

After researching this little-known area, Professor Qing Huang and associates suggested a generic A-site alloying approach. Because the chemical composition and crystal structure of MAX phases vary widely, this technique allows the synthesis of over 100 MAX phases with noble metal-occupied elements at the A-site of the crystals.

In particular, the A atomic layers contain one or more of the six noble metals (ruthenium, rhodium, palladium, iridium, platinum, and gold), with other solid solution A-site elements such as gallium, indium, germanium, tin, and others being chosen at random. The M-site elements are niobium, vanadium, and titanium.

Noble metal-occupied MAX phases with various geometries were created by selecting the source carbon powders. For the alkaline hydrogen evolution reaction, the Pt-occupied MAX phase generated in this work showed greater catalytic performance compared to commercial Pt/C, including lower overpotential, lower Tafel slope, higher mass activity, and better cyclic stability.

The noble metal-occupied MAX phases that result from general A-site alloying have a wide range of potential uses, including electrocatalysis.

This project was funded by the "Pioneer" and "Leading Goose" R&D Program of Zhejiang, the Zhejiang Province Special Support Program for High-level Talents, and the National Natural Science Foundation of China etc.

Journal Reference:

Li, Y., et al. (2024) A-site alloying-guided universal design of noble metal-based MAX phases. Matter. doi.org/10.1016/j.matt.2023.12.006.